Black oxide surface finish (aka blackening), which is a coating applied for mild corrosion resistance in dry environments. Black oxide treated metals/fasteners can rust in the right environments, so it should be stored properly to avoid rusting.

What is Black oxide surface finish or coating? #

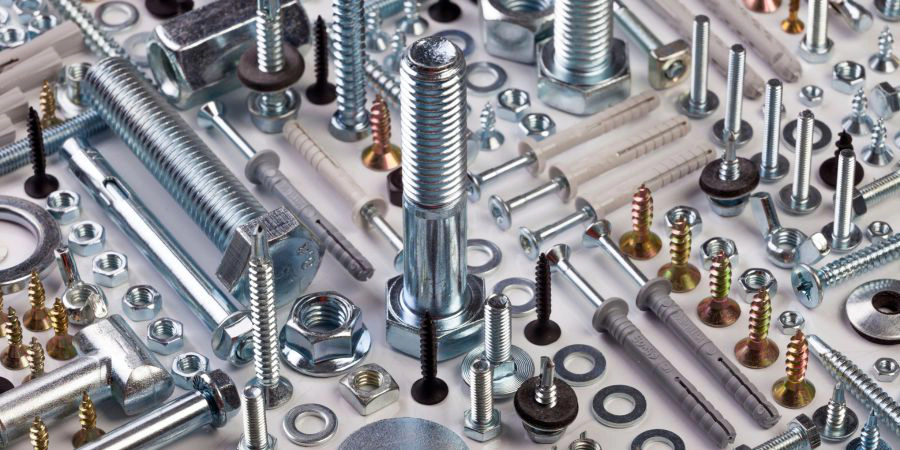

Black oxide surface finish (also known as blackening, gun bluing, or browning) is a type of surface finish for metal parts to improve their appearance (give a nice deep black color). Black oxide surface finish gives metals mild corrosion resistance in dry environments. Due to its low cost and simple process the black oxide coating is normally used for metal components iron/steel such as screws, nuts, bolts, and other fasteners. Black oxide surface finish is widely used in industrial, automotive, aerospace, and military.

Black oxide normally used on ferrous metal like steel & iron, but it can also be applied to other types of metals such as copper, brass, and aluminum.

Black oxide coating process #

Black oxide is not a coating, but a chemical process that converts the metals surface layer into black iron oxide. Hear is the simplified process of coating black oxide finish to metal parts. The entire process can take few minutes to several hours, depending on the thickness of the coating. To Speed up the process but higher temperatures can be used to speed up the reaction.

- The surface of the parts are cleaned to remove any dirt, grease, or other contaminants.

- Pickling by immersing the parts in done using a solution of hydrochloric acid or sulfuric acid.

- Black oxide coating process: The parts are then immersed in a solution of chemicals (for large parts the chemical is applied using brush or spray). The chemicals react with the metal to form a thin layer of oxide on the surface, giving the parts a black or dark gray appearance. [chemicals used depends on the type of metal being coated and the desired properties of the finished product]

- Rinsing & Drying: The parts are then rinsed and dried to remove any remaining chemical residues.

- Finally lubricants are applied to help prevent corrosion and improve their performance.

Pros and cons of black oxide surface finish #

Pros #

- Gives aesthetic appeal to metal parts (black or dark gray appearance)

- Low Cost when compared to other coatings (like, plating, galvanizing or anodizing)

- Compatibility with a lots of metals like steel, iron, brass, copper, and aluminum.

- Very thin coating, So Black oxide coating does not affect the components dimension/tolerance.

Cons #

- Black oxide coating give only mild protection to the metal from corrosion.

- Black oxide is sensitive to high temperatures and may fade if exposed to heat for long duration.

- Black oxide is not a powerful coating compared to coatings like galvanizing or anodizing. It is a thin layer of oxide on the surface of the metal, which provides minimal protection against corrosion and gives nice deep black look.

How to protect black oxide surface finish #

Here are the some tips to extend the lifespan of a black oxide coating and maintain its appearance.

- Regular cleaning to remove dirts.

- Applying oil, wax or grease.

- Don’t use harsh chemicals like acids, alkalis, or solvents for clearing the parts.

- Keep away from direct sunlight, Black oxide coatings are sensitive to UV light and can fade or degrade if exposed to direct sunlight.

- Always store the parts in dry container.

FAQ on Black oxide surface finish #

Here are some commonly asked questions about black oxide surface finish: